Mechanical Testing

Mechanical Testing Service

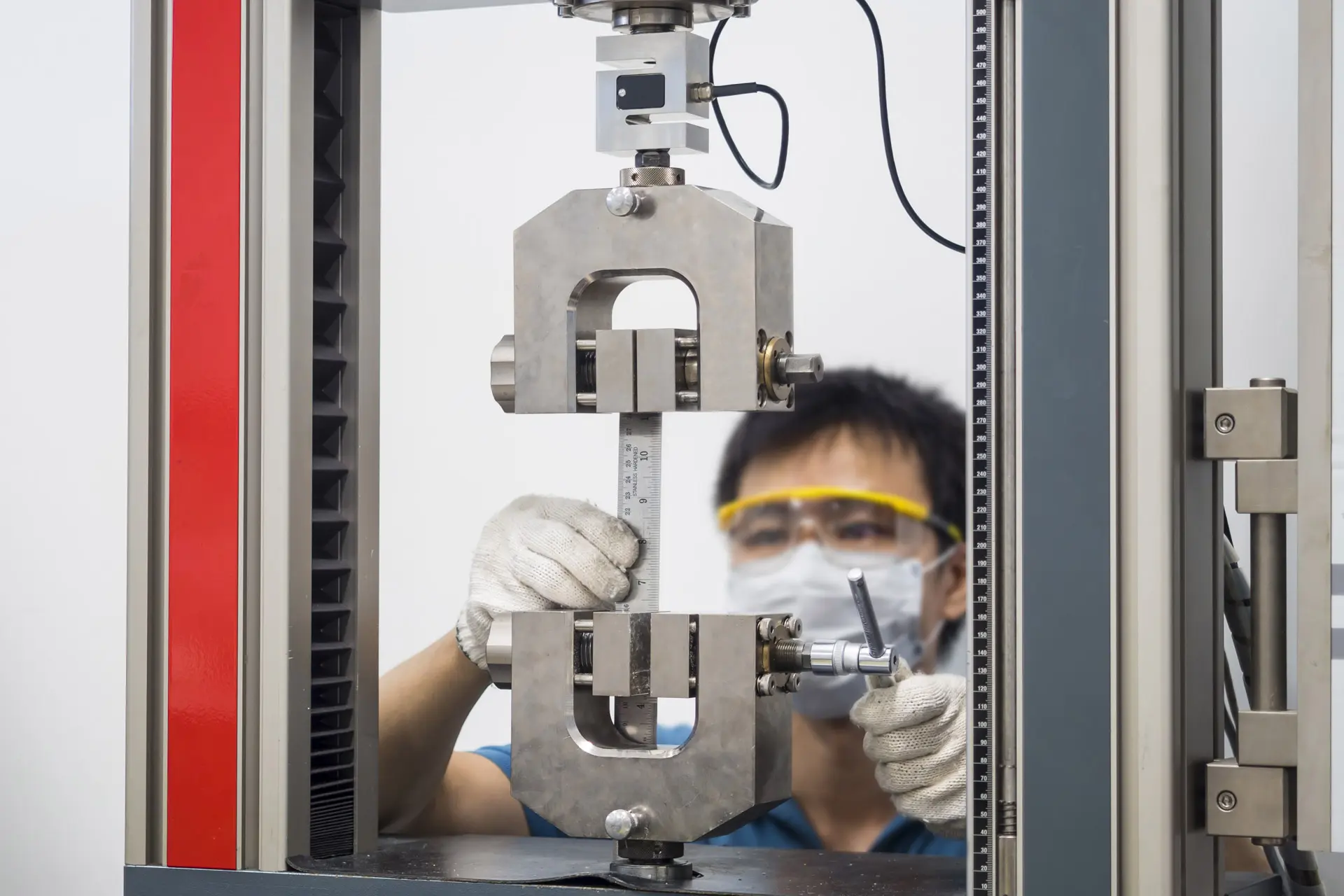

At AIM Inspection and Calibration Services, we are committed to providing precise and reliable mechanical testing services to ensure the integrity, performance, and safety of your materials and components. Our state-of-the-art laboratory is equipped with advanced testing equipment, and our highly skilled technicians adhere to the highest industry standards.

Our Mechanical Testing Services Include:

| Test | Description |

|---|---|

| Tensile Testing | Comprehensive evaluation of tensile strength, elongation, and yield strength of materials like plate, pipe, solid bar, welded materials, induction bends, castings, and fasteners. |

| Compression Testing | Evaluating the behavior of materials under compressive loads to ensure structural reliability. |

| Hardness Testing | Determines a material’s resistance to deformation using Brinell, Rockwell, and Vickers methods. |

| Impact Testing | Assesses material toughness via Charpy and Izod testing to measure energy absorption and resistance to brittle fracture. |

| Fatigue Testing | Evaluates material durability under cyclic loading to determine fatigue life and crack growth behavior. |

| Bend Testing | Determines ductility and soundness by bending materials to specific angles or until fracture. |

| Chemical Composition Analysis | Provides detailed analysis of chemical composition in accordance with ISO 17025 standards. |

| Macro & Micro Test | Macro tests examine weld fusion; micro tests assess grain structure and inclusions in materials. |

| Ferrite Test | Measures delta ferrite content in stainless steels to ensure corrosion resistance and structural integrity. |

| Fillet Fracture | Destructive testing to examine weld root penetration and failure points. |

| Nick Break Test | Reveals internal weld defects like slag inclusions and gas pockets through a controlled break. |

| Shear Testing | Assesses shear strength to evaluate resistance to sliding failure under shear loads. |

| Creep Testing | Evaluates material deformation over time under sustained load and high temperature. |

| Fracture Toughness Testing | Measures resistance of materials to crack propagation and sudden failure under stress. |

| Stress Rupture Testing | Assesses the time to rupture under constant stress and elevated temperature. |

| Flexural Testing | Measures material strength and stiffness under bending conditions. |

| Proof Load Testing | Determines the load-bearing capacity of components like ropes and chains using standards such as ASME B18, ASTM F606, and more. |

| Torque Testing | Assesses torque applied to components, particularly in fasteners, motors, and rotating parts. Standards include IFI 101, MIL-DTL-18240, NASM 1312, NASM 25027. |

Key Benefits of Our Mechanical Testing Services:

By choosing AIM Inspection and Calibration Services for your mechanical testing needs, you can trust that our team will deliver high-quality testing solutions that enhance the safety, performance, and reliability of your materials and components.

Ensuring reliable data for informed decision-making.

Verifying material and component performance and integrity.

Meeting industry and regulatory standards.

Providing detailed reports and recommendations based on test results.