INSPECTION SERVICE

INSPECTION SERVICE OVERVIEW

We are one of the major company that provides various Inspection services to the industries across the kingdom. Well qualified Inspectors are the most valuable asset of AIM and our solutions range from standard to advanced inspections. We deliver our best professional and competent Inspectors to our Clients for succeeding their various inspection requirements.

WELDER QUALIFICATION TESTING (WQT)

AIM comprises a team of Metallurgist, Engineers, Welding Engineers and technologist, Welding Supervisors and Inspectors,Engineering Technologist and Non-destructive testing Technologist. The combination of these professionals from different specialty ensures that the welding task is completed efficiently and within shortest duration.We provides the services such as Welding Procedure Specification (WPS), Weld Procedure Development, Welding Procedure Qualification record Witnessing (WPQR), Welder Qualification Witnessing (WQR), WPQR Weld Qualification, Welder (Performance) Qualification, Visual examination, Visual Inspection of welds, Non-destructive examination of welds and all mechanical tests related with WQT service.Our certified welding inspectors (CSWIP) conduct welding procedure qualification. Furthermore, they can develop welding procedures for use in the field.

AIM services help you to:

Develop welding procedures

Qualify welding procedures

Assess and qualify welders

Reduce costs and delays

NON-DESTRUCTIVE TESTING (NDT)

Our NDT service covers all the clients’ requirements in Nondestructive Testing around KSA. It’s comprised of a number of test methods that can detect surface and/or sub-surface defects without affecting the operating performance of the inspected products.

AIM has the largest Non-Destructive Testing division in Saudi Arabia, The team consists of experienced technician’s. We are equipped with the latest inspection tools and technology to the most advanced requirements of our offshore and onshore clients. AIM offers both conventional and advanced NDT testing methods for the detection of surface and sub-surface flaws in components.Our inspection solutions enhance the ability of following critical asset to comply with safety and environmental regulations, extend their life, increase productivity, minimize repair cost and manage risk and help to avoid shutdowns.

Conventional NDT Services

Radiographic Testing (RT)

Ultrasonic Testing (UT)

Magnetic Particle Examination (MT)

Dye Penetrant Testing(PT)

Advanced NDT Services

Automated Ultrasonic Testing (AUT)

Phased Array Ultrasonic Testing (PAUT)

Time Of Flight Diffraction(ToFD)

Magnetic Flux Leakage on Tank Floors (MFL)

Eddy Current Testing(ET)

LOCAL THIRD-PARTY INSPECTION SERVICE

AIM third party inspection services are one of the best in the kingdom. Our inspectors are well qualified and long term experience in this field. In various field there are various requirements of inspectors in projects during the design, construction, installation and commissioning and it will be very much risky and complex one for them to maintain so many workers at a time and it may cause minor to major failures in your projects. Sofor avoiding Quality issues and other problemsduring fabrication and site assembly give your inspection needs to AIM. We will reduce operational (quality, environment and safety) construction-risks in all projects.

Our services enable the client to monitor processes at every single stage and deal with concerns in a timely manner. It will also reduce the need for costly and unnecessary project rework and cost overruns.AIM can provide Project Compliance Certification on verification of all stages, from design to commissioning.

PMI SERVICES

AIM positive material identification Services has an expert and intelligent inspection workforce to perform incoming material inspection.We can provide on-site alloy verification for quality control and stock control purposes and analyze both melt and weld for extensive maintenance assessment.

AIM provides PMI services to to the various industries across the kingdom and our engineers can provide elemental identification and quantitative determination regardless of shape, sizeandform.

The team also conducts positive material identification test to detect carbon composition on-site.

Our PMI Service Method’s:

X-ray fluorescence (XRF)

optical emission spectrometer (OES)

PWHT SERVICES

AIM specifically an emerging company inthe field of performing PWHT service for the various industries across Saudi Arabia (Construction of oil and gas refineries, petrochemical plants, pressure vessels, pressure piping, buildings, bridges, storage tanks, power plants ,offshore platforms and steel and metal fabrication).AIM can provide PWHT service both on site/Off site. In our onsite facilities we can place numerous weldments/machined surfaces for PWHT. In addition, we provide a pick-up and delivery service. AIM can carry out PWHT in both offshore and onshore location utilizing our portable equipment.

AIMteam of highly skilled and experienced PWHT technicians makes sure that all weldments/machined surfaces brought in for treatment will meet the specified welding code requirements and be fit for purpose.AIM has the expertise to determine the mechanical properties of materials and resolve a wide variety of technical problems for the industries

Other Benefits of Our Quality PWHT Service

Reduced risk of brittle fracture

Improved or reduced hardness

Improved ductility material

Tempered metal

Removal of diffusible hydrogen

Relaxed thermal stress

LIFTING EQUIPMENT'S INSPECTION

We are one of the leading companyin Saudi Arabia for inspection, testing, verification and certification of all types of lifting equipment. Lifting equipment should be checked and maintained as necessary to keep it safe for use.Our inspection service assures you the safe and proper working capability and condition of your lifting equipment.

AIM can offer you the trusted inspection & certification for:

Material-handling devices:

Cranes

Derricks

Fork-lifts

Truck-mounted cranes

Shackles

Hooks

Elevating platforms

Tele handlers

Material-handling devices:

Elevators

Escalators

Ski lifts

Cable cars

Mobile elevating work platforms (MEWPs)

LIFE ASSESMENT

Life assessments adopt degradation mechanisms and their evolution using advanced analysis and simulation tools in the most demanding industries. It is important to maintain the critical components and the remaining life and analyse the considerations in extending the component life. The service life of components may fall or exceed related to the operational and metallurgical conditions and even end in terms of strength and longevity.

Life Assessment is most essential for safe and economy and necessary to keep equipment inefficient conditions. Suitable methodologies are utilised to avoid any issues and downtime problems.

Benefits

Assess fitness and service condition

Improve efficiency

Identifying areas of repair

Monitor the upgradations

Optimization

Reduce downtime

The scope of life assessment lies in the collation and review in operating life conditions. It may affect the life of the plant, includes prescribing targeted inspection and testing plans. The background information is reviewed and inspected with comprehensive documentation and recommendations.

We are experts in the same and have a deep understanding of the subject to assess the condition and equipment accurately and reliably to result in effective and practical solutions.

COUNSULTING SERVICES

ASME AUDIT SERVICE

ASME certification is the clearest way to tell customers, supply chain, industry, and regulators that your company is committed to public safety and quality. ASME Conformity Assessment program is the leading, universally recognized, independent Quality Assurance (QA) program that certifies that manufacturing, power generation, stamped products and parts fulfill the requirements of relevant ASME codes and standards. It certifies that stamped items conform to ASME standards, including the ASME Boiler and Pressure Vessel Code (BPVC), the Bioprocessing Equipment (BPE) Standard, and/or Reinforced Thermoset Plastic Corrosion Resistant Equipment (RTP-1) Standard. The Mark gives confidence that relevant QA processes, products and parts are safe, high-quality, reliable and consistent. In many countries, ASME certification is a means of complying with regulations, while also promoting global commerce.

AIM providing consultation for ASME Audit services locally in Saudi Arabia and gcc with focus on quality and service. Our Authorized Inspector Supervisor and ( AI) Authorized Inspectors, who are well qualified & experienced and provide inspection coverage throughout the country. We assuring you our best services at all times.

NDT LEVEL II TRAINING &CERTIFICATION

Nondestructive testing is recognized as a critical component for the safe operation of nearly every major industry worldwide. NDT training is an excellent idea because training is required for certification in the NDT methods, NDT training is an ideal way to obtain employment with these NDT skills. AIM provides best consultation for NDT LEVEL II training and certification throughout Saudi Arabia and gcc.

NDT LEVEL III TRAINING &CERTIFICATION

AIM Testing NDT Consulting Team has many years of individual and collective experience in the application of NDT technologies to a wide variety of complex problems.

Technical-Procedure Development.

NDT-Process Implementation.

NDT Engineering

Employee Certification

Process-Control Documentation

Process Auditing

Compliance-Audit Preparation

Radiation Safety support

CERTIFIED INSPECTORS OUTSOURCING:

AIM can assist you in outsourcing skilled inspectors for your large project. We can provide you with skilled, experienced and certified inspectors To meet the technical demands of complex projects, energy, engineering and construction companies. As a leading outsourcing consultant of technical staffing services. Our aim is to be your partner, taking care of all your technical staffing needs and allowing you to save time and money by reducing both recruitment time

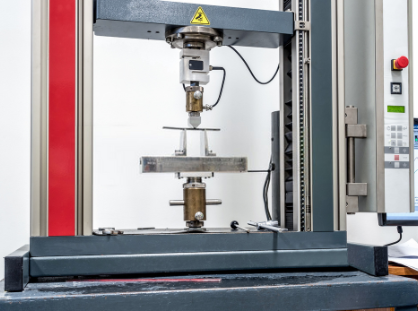

MECHANICAL TESTING

AIM specializes in the mechanical testing of metals, using latest technology and standard testing system that gives you the confidence you need to make an informed decision regarding your material. Our mechanical testing laboratory service provides quick and accurate test results.

We are providing The Following Mechanical Testing Services:-

1. Tensile Testing

AIM Provides tensile testing service. All tensile test specimens are testing to precise standards in our well-equipped mechanical lab to ensure that our data is reliable and accurate. These tensile tests give information on the strength and ductility of materials.

Our Tensile test scope:

Plate

Pipe

Solid Bar

Welded materials

Induction Bends

Castings

Fasteners

2. Impact Testing

Impact Testing is carried to find the toughness of material and weld specimens. It is a destructive method that measures a material’s toughness, ability to absorb energy and resistance to brittle fracture. AIM Mechanical lab provides accurate result in time for impact test.

3. Hardness Testing

Hardness testing helps to determine the capability of a material to resist wear, abrasion, deformation, penetration and machining. AIM is well equipped to perform all type of hardness tests depending on client requirements.

Hardness test methods:

Brinell hardness

Rockwell hardness

Vickers micro-hardness

4. Bend Testing

The bend test is a simple and inexpensive qualitative test that can be used to evaluate both the ductility and soundness of a material. Aim will provide you bend test faster with accurate result.

5. Chemical Composition Analysis

TChemical test is commonly doing to understand the composition and quality of chemical substances and materials that are used in products, manufacturing and industrial processes. AIM is an ISO 17025 Accredited laboratory for providing this chemical composition analysis.

6. Macro & Micro Test

To assess the grain structure of materials and identifies any inclusions in material is done by Micro examination. Macro examination is carried on weld fusion areas to check complete fusion and inclusions. AIM will provide both Micro & Macro examination with high quality test data and report.

7. Ferrite Test

Most commonly the ferrite test is used to measure the amount of delta ferrite on austenitic stainless steel and duplex stainless steel materials and Ensuring proper ferrite content ensures corrosion resistance, durability and crack prevention. AIM Ferrite testing is a fast, inexpensive, and accurate way to measure delta ferrite content in austenitic and duplex stainless steels.

8. Fillet Fracture

This is one soundness test which examining the root penetration in a destructive manner. the fillet fracture test examines the root penetration for the entirety of the specimen. The test includes the potential failure points of the weld which are the stop and restart of the weld. AIM have decades of hands-on experience in performing mechanical tests.

9. Nick Break Test

The Nick break test is carrying out to determine the internal quality of the weld metal. This test reveals various internal defects (if present), such as slag inclusions, gas pockets, lack of fusion, and oxidized or burned metal. AIM comprises a team of professionals to do these mechanical tests.

10. Fatigue Testing

AIM Fatigue testing is a specialized form of mechanical testing that is performed by applying cyclic loading to a coupon or structure. These tests are used either to generate fatigue life and crack growth data, identify critical locations or demonstrate the safety of a structure that may be susceptible to fatigue. Here at AIM we have the in-house expertise to test in specific standards or specific client needs.

11. Proof Load Testing

The proof load testing measure the tensile strength and load capacity of the material based on elongation under force. These test requires the lift of a specific type of material such as rope or chain using proof load test machines. AIM provides you this proof load testing by using most advanced technologies with high quality test data and report.

12. Torque Testing

Torque testing involves evaluation of the amount of torque being applied to an object. Two of the more common applications for torque testing are in fastening and in products with rotating parts such as motors, engines or transmissions.

ASME B18

ASTM F606

IFI 101

MIL-DTL-18240

MIL-F-18240

NASM 1312

NASM 25027

CIVIL TESTING

AIM is one of the leading authorities in the kingdom that provides geotechnical services for in various sectors. We provide world-class services for soil testing & construction material testing in our wellequipped laboratory with highly qualified engineers and technicians with strong background experience in soil and materials testing.

1. Soil Test

For civil engineering analyses of land, we are one of the best service providers in the kingdom. Our laboratory research forms the basis of well-founded geotechnical advice and we are specialized in mineralogy, chemistry, geology, and materials science into a unique soil testing lab.

Test conducted in our laboratory are:

Chloride Content

Electrical Resistivity

Linear Shrinkage

Modified Procter Compaction Test

Organic Matter Content

CBR In Situ

CBR Laboratory, Soaked Single Point

Particle Size Distribution by Hygrometer, Sieve Analysis and Hygrometer

2. Construction Materials Test

AIM testing department cover a wide range of specialized services in the field of construction. AIM will conduct the material testing with international standards and our laboratory is equipped with standard machineries.

Aim provides the following materials testing in the field of construction:

Concrete Testing

Concrete Mix Design

Brick Testing

Tiles Testing

Mortar Testing

Cement Testing

Aggregate Testing

Quality never comes up accidentally,it is obtained from proper inspection and upgraded production process